|

The RoHS Directive and the UK RoHS regulations came into force on July 1, 2006. However, long before the international requirements were enforced, Paragon already ensured that the raw materials used for watch crystal production comes from reliable sources. The materials used in our production comes from renowned suppliers with proven technology and management systems, ensuring that our products are friendly to the environment.

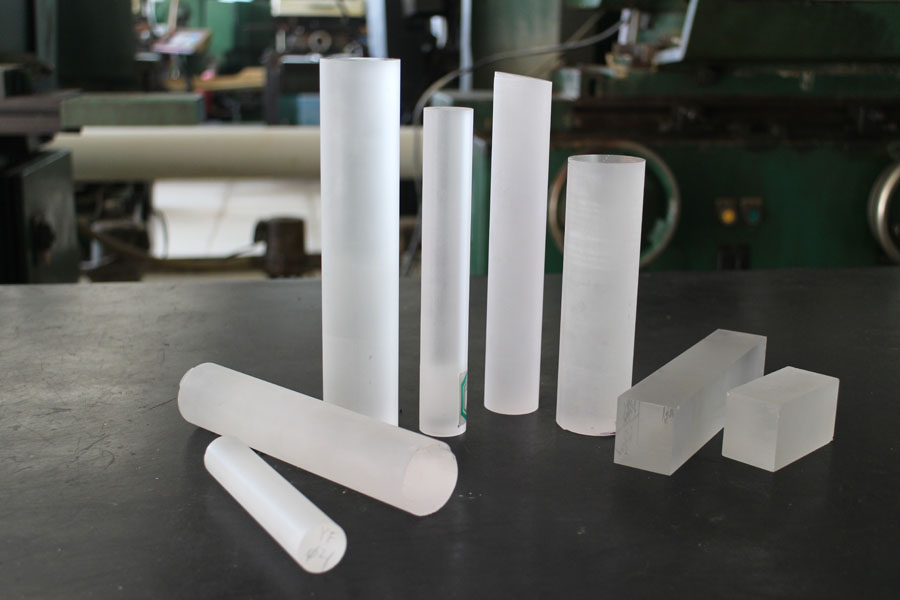

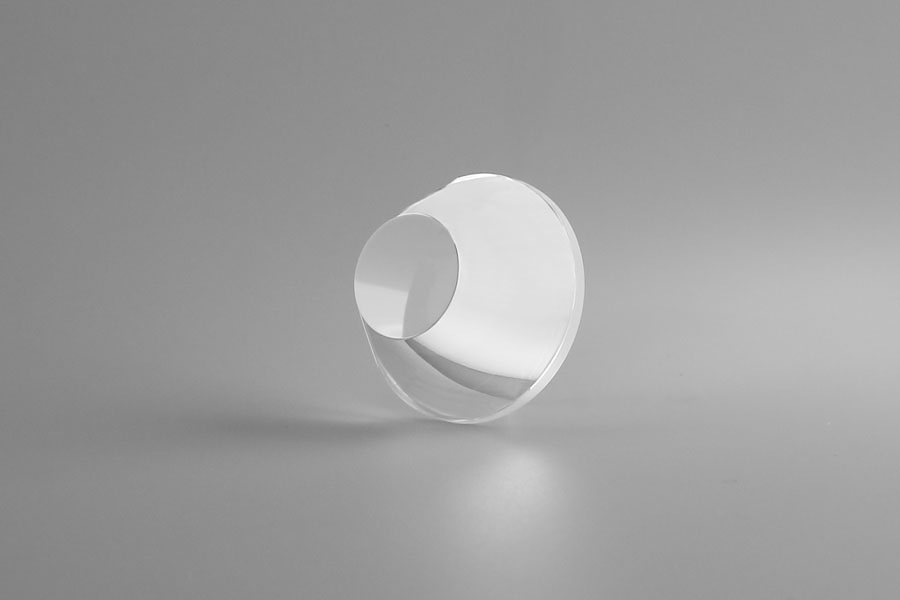

Due to its chemical, mechanical, optical and structural properties, Sapphire has been widely used for making watch crystals, mobile phones covers, and camera cover lens.

Technical Characteristics of Sapphire:

- Scratch- resistant with a hardness of 9 on the Mohs scale

- High dielectric constant

- Good light transmission in the VIS region

- Refractory temperature tolerance from within a few hundred degrees to its 2040°C melting point

- Excellent thermal shock resistance due to high strength and high thermal conductivity

- High mechanical strength at high and low temperatures

- Chemical resistivity stable in many acid environments at high temperatures

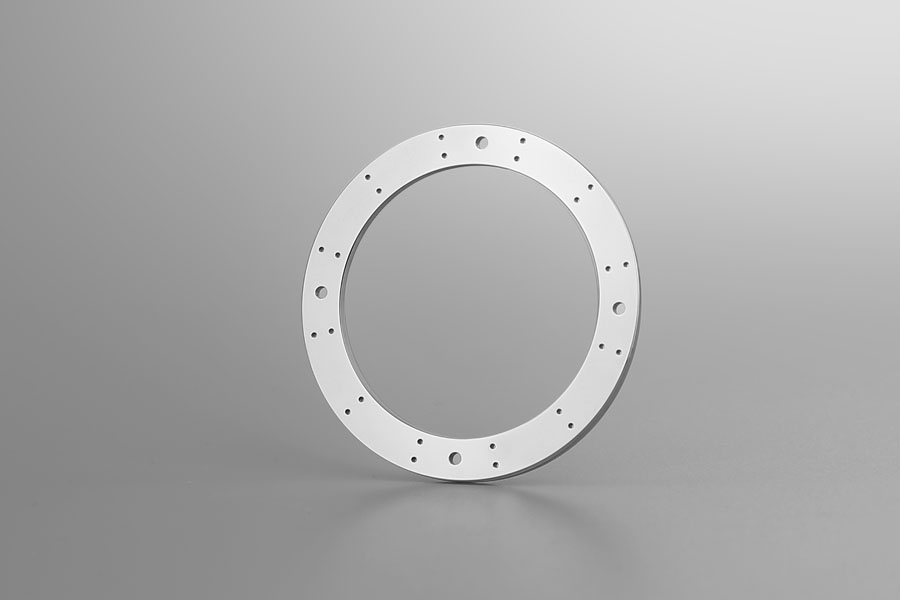

Paragon specializes in polishing glass for watches, mobile device, optical and other applications.

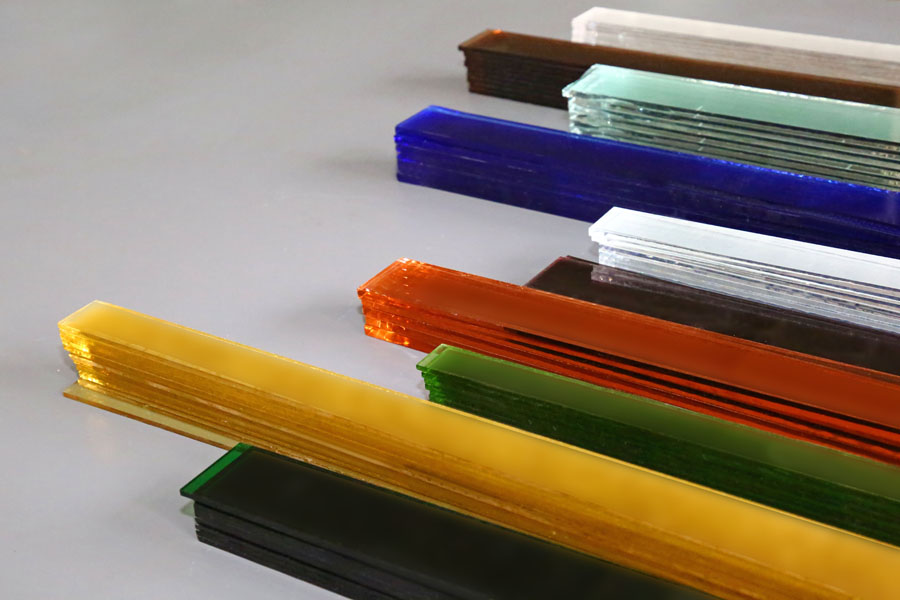

Chemically strengthened glass, such as Corning Gorilla Glass, Dragontrail Glass and Asahi, are commonly used for the cover glass of portable equipment. These materials are stronger than conventional soda lime glass and are available in a variety of thickness.

We are equipped with production capability to meet our customers' requirements of using different materials in the optical industry and for other applications. These glass materials include Sodalime, B270, BK-7, K1, CX-01 and colored glass etc.

|